What’s the Difference Between Sound-Absorbing and Diffuser Materials?

Most architects and interior designers love the bespoke rooms and have an eye for detail when it comes to visual design. However, they can get clueless when a client requests for acoustic specifications in their projects be it commercial or residential.

Acoustic panels are products which can be used to control the sound quality of different spaces. They may be classified into three categories based on their absorption and diffusion properties.

These three categories are: porous absorption materials, resonant absorptive materials, and diffuser:

-For porous Absorptive Materials, its features rely on the pore structure inside the material to absorb sound energy and convert sound waves into heat energy.

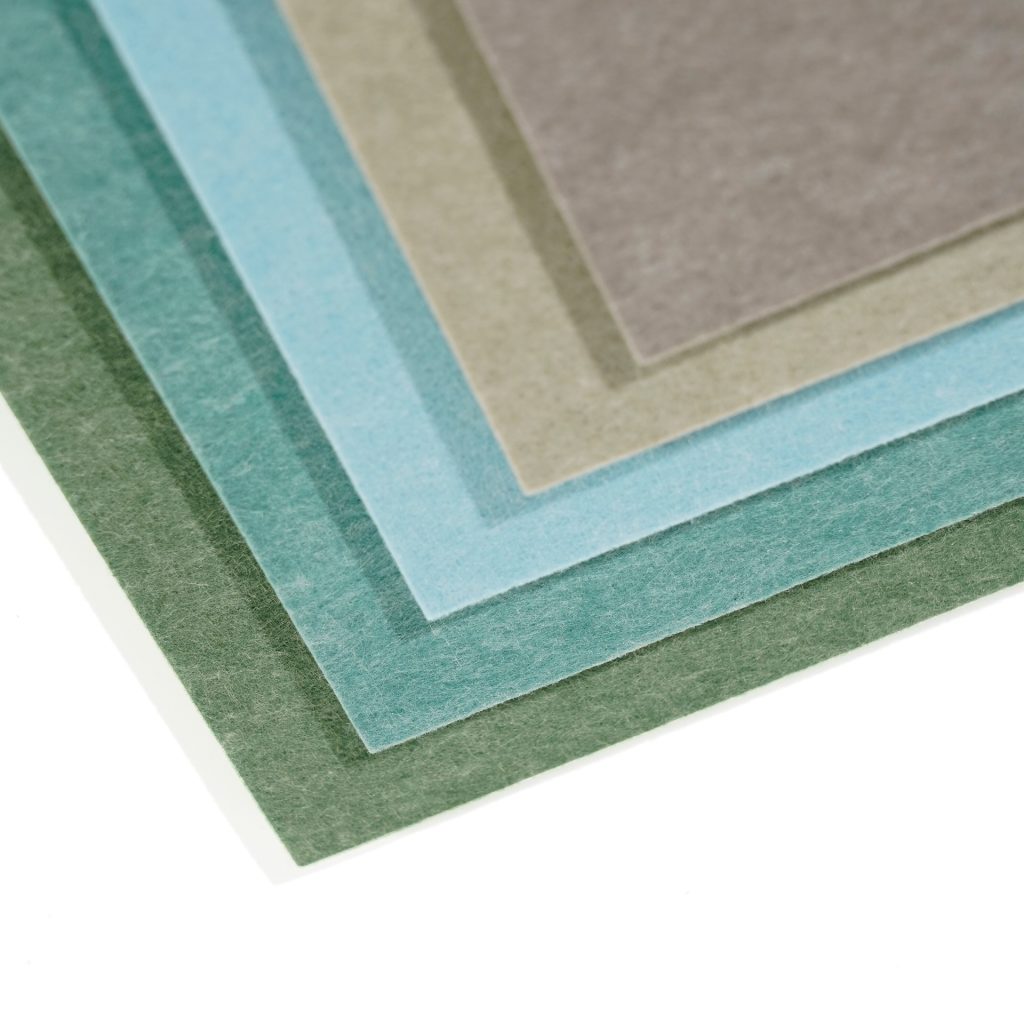

Common materials such as polyester fiber (for example PET sound-absorbing panels), glass wool, mineral wool, foam, etc. Advantages are good absorption effect on medium and high frequency sounds. And popular applicable scenarios are offices, conference rooms, theaters, recording studios, etc.

-For resonant Absorptive Materials, its features are to absorb sound waves of specific frequencies, especially low frequencies, through the resonance of the plate or membrane material and the rear air cavity. Their common forms are perforated plates, slotted plates, thin plate resonators, etc. With advantages of good absorption effect on low frequencies. Widely ued for concert halls, studios, low-frequency noise control places.

-For diffusive Acoustic Materials / diffusers, its features: Instead of absorbing sound energy, it evenly reflects sound through irregular surfaces, breaks up the direction of sound waves, reduces standing waves and echoes, and improves the uniformity of the sound field. And their common forms: QRD diffusers, two-dimensional diffusers, irregular geometric surfaces. With advantages of improving spatial acoustic uniformity and eliminates “dead sound”. Used for concert halls, recording studios, home theaters, high-end conference rooms, etc.

To understand these categories, it is necessary to understand the basic differences between absorption and diffusion. Sound energy striking a surface may either be transmitted, absorbed, or reflected; the amount of either of these depends on the acoustic property of the surface.

Absorbers are used to reduce the noise levels in a room by absorbing the sound energy.

Diffusers are used in spaces to make the room sound lively without creating echoes. Diffusers do not absorb the sound energy but instead disperse the sound uniformly within the space without removing sound energy.

An example of a use of diffusers is in concert halls where there is a requirement for the uniform reverberant field. In many cases, absorbers and diffusers are used in a room together for optimum results. Absorption may be used in locations where early reflections occur—to minimize interference with the direct sound. Diffusers make the room lively by providing reflections to produce a uniform diffuse field.

Polyester fiber board is made of 100% polyester fiber cotton, which is high-temperature agglutinated and pressed by low melting fiber. Polyester fiber cotton is divided into thick fiber and thin fiber. Thin fiber is known as memory foam, and thick fiber is a kind more elastic mainly used as sofa and mattress fillings. It seems like texture wool feelings after high-temperature press.

Content of formaldehyde is very low after not using rubber products in our whole procedure, to completely reach the international formaldehyde standard.

Polyester fiberboard is a material used by large-scale and high-standard acoustic engineering projects at abroad and home, with strict standards and test effects on its acoustic data and construction process methods. It is excellently friendly to the acoustic design, and thus can be directly inserted into the acoustic design software to calculate the reverberation of the whole room.

The sound absorption characteristics of polyester fiberboard are very excellent. It comes with a high-frequency absorption coefficient of 2000Hz in the wall, and the absorption coefficient of low frequency is increasing as the thickness of the product cavity increases. The installed cavity can increase from 50mm to l00mm, 150mm, and 200mm, and its low-frequency sound absorption coefficient will increase significantly along with the cavity depth.

When the product cavity is 200mm, the sound absorption coefficient is high from the entire test frequency range of 100 to 5000 Hz, used as full-band sound-absorbing material. The sound-absorbing coefficient can reach above 0.9 in performance.